DROPPING MACHINE

AMI EVO

In a very simple manner, these machines can produce a wide variety of biscuits and pastries.

The Kalmeijer biscuit machine can handle sweet doughs for cakes, jams, Viennese biscuits, gingerbread, Christmas cookies, and more. Since there is no friction or pressure applied to the dough in the biscuit machine, it is possible to use doughs with fat content ranging from 30% to 70% and sugar content of at least 30% (relative to 100% flour). This means that with our biscuit machines, you can use sweet doughs from your own recipes and create cookies in your own designs. If you have any questions about your recipe for the biscuit machine, you can contact our test baker for more information. For new ideas, download various biscuit machine recipes.

Machines for producing ice cream cones and cups of any size and shape. The best machines for small-scale production and/or sampling. Heating is electric. Production capacity up to 400 pieces per hour.

Simple, very sturdy, and reliable, these machines can be easily operated by unskilled workers. They feature advanced and modern technology with automatic temperature control for the top and bottom molds, and automatic programmable baking time control.

It can be placed on a sturdy table or a suitable frame. It comes with a manual with instructions and a complete recipe for dough preparation. Mold feeding is done via a special dosimeter and reservoir, with electric heating. The molds are opened and closed using manual levers. Cones are automatically ejected into a container located below the molds.

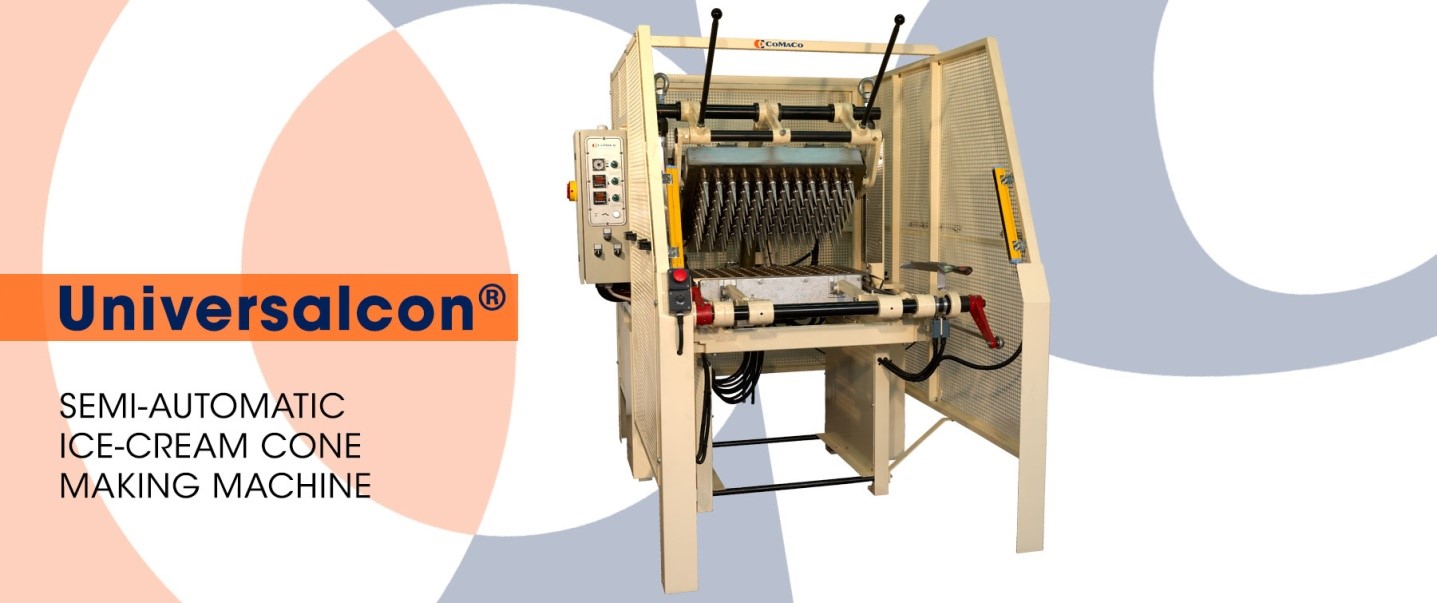

Semi-automatic machines for producing ice cream cones and cups of any shape. The molds are of standard dimensions and are interchangeable. Heating can be electric (any voltage), natural gas, or liquid gas. The capacity ranges from 1200 to 5500 pieces per hour.

The molds can have 5, 6, 7, 8, or 9 rows. Automatic baking temperature control; the machine maintains the pre-set temperature and provides audible and visual alarms at the end of the baking cycle. The molds open and close using an automatic system operated by the user and powered by pneumatic cylinders. Molds are filled through a special filling device; a dosimeter. Cones are automatically ejected into a container at the bottom of the machine when using the lower mold. The machines are supplied with all operational instructions, including a recipe for making waffle cones.

MINIROTARCON®

To start making cones, cigars, baskets/shells, etc., these convenient professional electric machines are the best solution. Wafers produced using various recipes (the basic recipe is provided by our company) can be shaped into multiple forms with the appropriate accessories: rolled sugar cones, cigars or cigarettes, baskets, and more.

Automatic machine for producing flat wafers or rolled sugar cones and/or cigars and bowls/baskets/shells. Electric heating.

Exceptionally versatile, the ROTARCON® features 9, 12, or 18 molds with a simple and very fast exchange system. Adjustable automatic multi-point pump ensures precise and even injection of dough into molds. The capacity depends on the type of product, size, and the dough used. Automatic temperature control. A wide range of available accessories allows for the production of a variety of products with the best quality.

4-plate carousel for sticks

Set of 4 independent plates mounted on a rotating stainless steel chassis. Variable speed. Control pedal for stopping and starting.

Aluminum drip tray for catching spills. Protective guard for the safety of the operator.

Estimated output: 240 products per hour

Spring rolls

Traditionally, spring rolls are festive food in Vietnam. Popular in the old imperial court, they are usually known as imperial pastries or imperial rolls in France, spring rolls in Quebec, and fried spring rolls, spring rolls, or Vietnamese rolls in English-speaking countries and Hong Kong. They can be made from traditional rice paper. There are also varieties made using wheat flour galette.

SDTN-KREPELEK provides automatic solutions for waffle production.

Set of 6 independent plates mounted on a rotating stainless steel chassis. Control pedal for stopping and starting

Available options:

Automatic dough dispenser

Automatic waffle plate opener

Output:

With 2 waffle plates: between 120 and 240 waffles per hour (depending on cooking time, 4 or 2 minutes)

With 4 waffle plates: between 240 and 480 waffles per hour (depending on cooking time, 4 or 2 minutes)

Ice cream cone

SDTN-KREPELEK produces a craft solution for ice cream cone production.

Output: between 60 and 120 products per hour (depending on cooking time, 4 or 2 minutes)