T8 TEMPERING MACHINE

The T8 TEMPERING MACHINE has all the Pomati attributes: a heated and thermo-sealed chocolate tank, digital and thermo-sealed temperature controls. With its 9 kg maximum capacity, this machine is an ideal assistant for small chocolate and pastry labs.

The machine is available in various sizes and capacities.

Enrobing belt

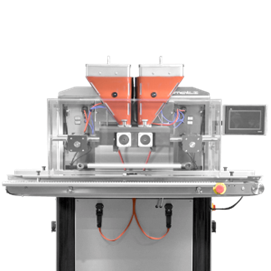

Topping Dispenser

A machine designed to facilitate the application of decorations and sprinkles on chocolate-coated products.

Transform your tempering machine into a LINE.

275×175 or 275×135 mm System for filling, dosing, and rotating polycarbonate molds for chocolates, chocolate bars, wafers, etc. Can be combined with the Pomati Tipper mold model for making hollow shapes such as chocolate cups, shells, Easter eggs, etc.

Phase 1: Filling tower for molds with a capacity of 15 pieces.

Phase 2: Chocolate dosing with a pneumatic valve combined with a heated adjustable dosing plate. Operation via a touch-sensitive screen.

Phase 3: Continuous or time-limited vibration.

OSD 10

The One Shot Depositor OSD-10 allows for the production of up to 360 molds per hour of ultra-thin, filled, and custom chocolate shapes. For this reason, its ease of use and production time optimization can be surprising: quick cleaning enables format changes in no time.

OSM – Mold Loader with Preheating Function

Designed for the automatic filling and preheating of polycarbonate molds (175×275). The molds are fed by a loading tower to a preheating step achieved with four infrared lamps inside the cover. Loading can be done manually or automatically, connected to existing machines. Heating speed and temperature are controlled by a simple control panel.

Available for:

One Shot Depositor OSD-5

One Shot Depositor OSD-10

Perfect cooling is not just a matter of temperature.

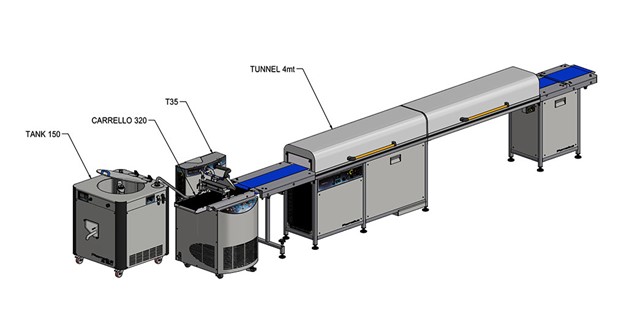

Rapidly designed and built for cooling products such as chocolate Easter eggs, cookies, and coated candies, the POMATI Cooling Tunnel is ideal for both artisanal and industrial factories. The warm product is conveyed into the tunnel via a conveyor belt, where it is cooled with low-temperature forced air. The cooling system and conveyor belt are activated manually using the control panel.

The first Pomati tunnel in a vertical version

Verticale Pomati: a vertical tunnel that cools as efficiently as a 20-meter tunnel within just 2 meters of width, achieving a 90% reduction in overall dimensions. The Verticale can be adapted to existing production lines, reducing their footprint while enhancing their performance. The innovative cooling system ensures homogeneous distribution of cold air within the chamber. Air recirculation combined with a high-efficiency cooling unit reduces energy consumption and maintains low humidity levels. Brushless motors, controlled by servo drives, allow for smooth handling of carriers. Cooling temperatures and times can be programmed via a touch-sensitive screen. The unique design enables installation in open laboratories.

For any type of laboratory

Vitti, an automatic dosing machine for filling pralines, bars, macarons, and jars of various viscosities.

From soft dough, you can produce cream puffs, éclairs, macarons, and other types of small filled pastries.

Ease of use, quick cleaning, and rapid format changes make the Vitti machine suitable for any type of laboratory.

The machine is made entirely of AISI 304 stainless steel. Suitable for small to medium production, it is ideal for chocolate coatings for almonds, hazelnuts, coffee beans, puffed rice, and various other products. Capacity of up to 8 or 16 kg of product per work cycle. The machine is equipped with a heat pump for generating hot and cold air: cold air for puffing products during the coating phase; hot air for smoothing, glossing, and final polishing. From the touch-screen control panel, you can adjust the temperature, speed, and drum rotation direction.

Complete Production Lines

Cook-Matic is a professional tartlet machine. Cook-Matic allows you to form and bake tartlets from shortcrust, savory, crumbly, and puff pastry. By combining two plates, Cook-Matic enables you to produce tartlets in various shapes and sizes, ready for filling and decorating as desired.

Cook-Matic, the tartlet baking machine, is easy to use: simply set the desired temperature, baking time, and press Start. It is possible to adjust two different temperatures between the top and bottom plates to ensure perfect baking of the products.

An audible signal will notify you when the cooking is complete. The resulting product will have the quality and taste of homemade tartlets but with significantly lower production costs.

CHECREMA is a professional compact cream cooking machine, perfect for preparing small quantities of always fresh products. With CHECREMA, you can finally offer your clients the highest possible quality by dramatically reducing processing time. Due to its compact design, CHECREMA becomes an essential machine for use in bakeries, patisseries, and restaurants.

Using CHECREMA, all processes are automated and faster and easier than before.

Strengths of CHECREMA:

– Compact size

– Low energy consumption

– Precise temperature control

– Easy (step-by-step) recipe setup procedure

– Adjustable mixer speed via inverter

– Transparent lid for monitoring the product throughout the process

– Quick buttons for heating and conserving creams