Packaging machines for your products with smaller capacities

WEBOMATIC SINGLE-CHAMBER MACHINES  odlikuje ih robustan i izdržljiv dizajn, jednostavno održavanje,procedure čišćenja i intuitivan rad putem elektronskih kontrola.Naše jednokomorne vakuum mašine idealne su za veće proizvode i povećane potrebe za pakovanjem.Dostupni su sa dodatnim opcijama kao što su MAP, Soft Air tehnologija i različitim sistemima zaptivanja kao što je biaktivno zaptivanje.

odlikuje ih robustan i izdržljiv dizajn, jednostavno održavanje,procedure čišćenja i intuitivan rad putem elektronskih kontrola.Naše jednokomorne vakuum mašine idealne su za veće proizvode i povećane potrebe za pakovanjem.Dostupni su sa dodatnim opcijama kao što su MAP, Soft Air tehnologija i različitim sistemima zaptivanja kao što je biaktivno zaptivanje.

WEBOMATIC® COLLECTION MACHINES

WEBOMATIC packaging and drying units are designed to significantly improve the presentation of your final product.

These units deliver exceptional results with advanced temperature penetration and energy efficiency. The hot water gathers the pre-sealed vacuum shrink wraps around the product like a second skin. Compared to traditional vacuum packaging, shrink packaging offers wrinkle-free transparency, ensuring your products are always packed to perfection. In addition, they prevent liquid from escaping from the product and can further extend the product’s life.

Furthermore, their precise and accurate construction makes them easy to handle and control.

You can seamlessly integrate these units into your existing production line or new setup, providing a simple solution to increase productivity

WEBOMATIC Container sealer TL 250

The container sealer WEBOMATIC® TL 250 is easy to use, hygienic, reliable and, above all, versatile. It effortlessly covers the packaging needs in trade and catering or for the production of sample packaging in laboratories and industry. Due to its compact dimensions, as well as the robust construction that is easy to service, the Tray Sealer TL 250 can also be used in small spaces or in corners. WEBOMATIC® Chamber Tape Machine CL-C 950

Ideal for medium to large production capacities is the CL-C 950 in many areas of application, the best solution for fully automatic and economical bagging. The WEBOMATIC CL-C 950 offers the best ease of use, reliable efficiency and is very versatile. Products of the most varied sizes can be flexibly pack in one process. WEBOMATIC ML-C 2600

The smallest thermoforming machine ML-C 2600 is available for growing craft businesses and supermarkets. This “entry level” packaging machine is the best start for individual packaging of sliced fresh meat or sliced meat products of small to medium capacity.

The ML-C 2600 is a packaging machine that is compact and only 3.7 meters long, making it suitable for use in various locations.

It efficiently produces high-quality packaging on a small scale while saving time and money.

An optional quick-change system for sealing plates saves a lot of time when there are several format changes per shift, and step-by-step instructions on the monitor make it easy for operators to familiarize themselves with the system.

The machine can process rigid films up to 600 microns thick and 422 mm wide.

The specific features and specifications of the machine determine the eight different draw lengths of up to 300 mm that it can achieve.

LARGE CAPACITY INDUSTRIAL MACHINES

WEBOMATIC® Chamber tape machine CL-C 950

Ideal for medium to large production capacities is the CL-C 950 in many areas of application, the best solution for fully automatic and economical bagging. The WEBOMATIC CL-C 950 offers the best ease of use, reliable efficiency and is very versatile. Products of the most varied sizes can be flexibly pack in one process.

WEBOMATIC® TL-750

The TL 750 is the entry into high-speed packaging of industrial packaging capacity.

Tray Sealer TL-750

Thanks to the perfect combination of innovation, design, performance and a well-thought-out concept of integrated standards and expandable options, the tray sealer enables efficient production on an industrial scale.

Whether it’s meat, fish, poultry, cheese, bakery products or seafood: WEBOMATIC container seals guarantee optimal product presentation.

WEBOMATIC® ML-C 5600

This thermoforming machine, which is designed to meet the highest requirements for industrial production, impresses with its high performance, quality and ease of maintenance and service. of rigid foils, suitable for special foils and the formation of the top film. – processes film width up to 562 mm, repeat length up to 600 mm. – Optimum power distribution and adhesion system of double knee levers. – High degree of adjustment. ML-C 5600 is suitable for work at high speed.

The innovative thermoforming machine, equipped with highly dynamic servo motors, is made with special emphasis on preventing dirt from settling.

With its film width, repeat length/index and optimized lifting motion, the machine is ideal for automated work in a packaging line with integrated cutters, pick-and-place robots, multi-head scales, etc.

Depending on the specification, it can produce rigid films up to 600 µm with a width of up to 562 mm and an index length of up to 600 mm.

Fully automatic Tray Sealers TL1150 and TL 1350

WEBOMATIC® container seals represent process reliability and the highest precision, even for critical products.

The WEBOMATIC® TL 1150 TL 1350 offer adaptable, high-tech packaging technology that is an unrivaled tray sealing solution for large industrial volumes.

With WEBOMATIC Multitools, Skin or MAP packages are created with the same tool.

Thanks to WEBOMATIC® SCC, in case of failure, each cavity can be closed individually while production continues without interruption.

F1000 – F2000 F4000

The line consists of 5 models with different characteristics.

Designed to meet different needs from supermarket chains, retail stores to Ho.Re.Ca, the different lines have been developed to fully meet the needs of small daily productions, maintaining a high standard of quality.

The machines are designed to simplify the daily work of operators and to meet the growing demands of customers; Molds of various shapes and sizes can be used not only for meat, but also for fish and preparations for vegetarians and vegans.

The weight of the hamburger remains constant and perfectly set, meeting the standards required in the production and packaging industry, where product quantities must be precisely defined.

All equipment is made of high-quality materials, stainless steel and aluminum alloys, properly treated for contact with food.

Durable, easy to use and easy to clean, the burger molds are equipped with an ergonomic conveyor belt that makes it easy to get the burgers out.

All burger molds meet the requirements of the current EC directives – CE mark.

ETL and NSF designations are available for some types of patty makers.

All equipment is made of high-quality materials, stainless steel and aluminum alloys, properly treated for contact with food.

Durable, easy to use and easy to clean, the burger molds are equipped with an ergonomic conveyor belt that makes it easy to get the burgers out.

All burger molds meet the requirements of the current EC directives – CE mark.

ETL and NSF designations are available for some types of patty makers.

CUTER Titan 120 V

We offer a wide range of cutters of unsurpassed quality, with capacities from 20L to 200L. They provide the best results for both coarse grinding and the production of delicate dough.

CAST STAINLESS STEEL BOWL FROM 2 TO 3 CM | CHAPTER 6 KNIVES

BACK MIXING SPEED 150 TO 300 RPM

VARIABLE KNIFE SPEEDS 1000 TO 4000 RPM

In accordance with CE standards

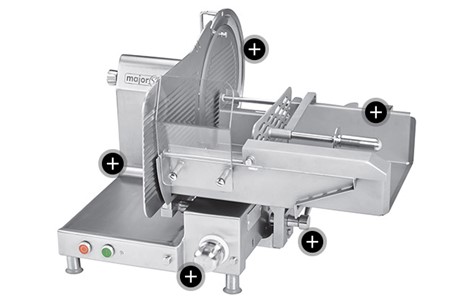

MAJOR SLICE 350 VERTICAL

Our “Major Slice” prosciutto cutters are unique on the market. It is strong and precise, which enables a perfect cut with its reliable operation. Its completely stainless steel and open design ensure easy cleaning and complete hygiene.

CLOSED AND CAN BE CLEANED WITH HAND SPRAY | FULL ACCESSIBILITY FOR CLEANING

AVAILABLE IN TWO VERSIONS: A MEAT TROLLEY OR A TROLLEY FOR EARLS

100% STAINLESS STEEL | INCLUDED WITH VARIOCUT SYSTEM | PINION DRIVE

Kriolit

The volume, quality, hygiene and finish of our range have made it the market standard.

MIXERS FOR MEAT

Our mixers are powerful and practical and ensure that you get a homogeneous mixture that will retain the texture of the meat.

Our mixers are ideal for making all fillings and marinades, respecting the texture of the product.

Advanced vacuum filler for medium and high production

RS 305 is a Risco electronic continuous vacuum filler intended for medium and high food production. Filter RS 305 is a compact, precise and reliable machine. It features the well-proven characteristics of Risco servo-driven fillers, namely durability and reliability. This model is equipped with a new multi-function HMI. HMI enables direct and efficient monitoring of the entire machine in order to speed up and optimize daily food production. In addition, the operator can easily recall all production programs and immediately switch to other products. In addition, the filler RS 305 is extremely versatile and suitable for any food processing. The optimized feeding system enables perfect filling of the Risco LongLife pump. Thus, you can achieve gentle and precise filling of any type of sausage or food. Furthermore, you can connect the RS 305 filler to all Risco accessories from the advanced range. In this way, you can get an optimal and wide production system.

Main features Precise portion weight control Excellent definition and compactness of the final product Increased production efficiency with large portions Simple navigation through programs with icons Compact design Silent operation Reduced carrying costs Technical characteristics Production per hour: 4,900 kg/h Portioning speed: 680 pcs/min Filling pressure: 40 bar max Installed power: 8 kW Tank capacity: 280 liters

RS 260 + RS 279

Advanced semi-automatic twisting and hanging system, for efficient production of high-quality sausages

In the RS 260 system, Risco continuous vacuum filling with low pressure discharge technology feeds the twisting mechanism in a constant, delicate and efficient manner. When the casing wears out, the charging tube quickly moves to the side, allowing the operator to quickly insert a new rod. A two-handed impulse system returns the barrel to the charging position, ready for restarting. This automation ensures a significant reduction in production downtime, for higher yield and constant production quality. In addition to the hanging unit, the RS 260 also ensures the correct position of the twisted product in shaped hooks, which the operator can remove for the next stage of the process. The overall production performance with the RS 260 solution is significantly improved compared to the traditional twist-linker, especially for products of unsurpassed quality.

Compact mold for homemade hamburgers

The ATM 201 forming machine is the ultimate forming equipment for fabrication meat and meatless homemade hamburgers. The system includes a pneumatic cutting device synchronized with the latest Risco filling machines and a powerful leveling belt with a servo motor. The perfect combination of these components ensures the fastest and most accurate portioning of high-quality meat, fish and vegetarian specialties. The ATM 201 forming machine comes with a frame on wheels for easy connection and disconnection from the Risco filling machine during daily production

Meat grinder for fresh or tempered meat

The Risco automatic grinder TR 200 has a cutting plate diameter of 200 mm and is used for grinding fresh and seasoned meat. The feeding auger, placed at the bottom of the large tank, is positioned at an angle of 90° in relation to the grinding auger, allowing to maintain the excellent quality of the processed product. Different combinations of knives and plates are available, which enable high productivity and a higher quality product. The grinder can be connected to a boning system. All parts are easily removed to allow for quick cleaning at the end of the day.

Main characteristics

It allows maintaining the structure and appearance of the raw material

Solid design with rounded corners

There is no temperature rise during the process

Available with single or double cutting system

Easily disassembled for cleaning and inspection

Type H(N)SKR ili H(N)SKL

2 roller systems for thorough hair removal Head scrubber holder for hard-to-reach areas of the head Mobile on 4 wheels Reinforced gears of new design Special scraping blades (also on the back plate) Electric heater in the oil bath Integrated control and management unit in the machine housing Rotating rollers for cleaning the machine

Machine for hair removal and baking Type Goliat

The Goliath dehairing machine is suitable for dehairing pigs and sows at a rate of 50 to 120 pigs/hour. This heavy-duty single-chamber shaver roller system is also suitable for sows and boars weighing up to 400.

Slaughter capacity: approx. 50 – 120 pigs/hour

Max. weight of the pig: approx. 400 kg

Exterior of the machine in a hot-dip galvanized design

Built-in control cabinet

A roller equipped with special scraping blades with metal razors

Hair removal time and machine filling

Individually adjustable

Machine frame hot-dip galvanized,

Stainless steel doors and central cabinet

CORTEX CB 496 DERINDER

Debarking machine with medium length conveyor for automatic processing and for “manual” debarking with open top

ICE MAKERS – NSH400

A flake ice maker with a daily output of about 400 kg of flake ice in 24 hours

MEAT SPECIALIST with a large chamber volume. Regardless of whether it is red meat or poultry, fresh or frozen, the unique 4-sided pre-pressing guarantees the highest cutting quality. The extra long working chamber ensures high throughput and minimal preparation effort.

Advanced vacuum filler for medium and high production

RS 305 is a Risco electronic continuous vacuum filler intended for medium and high food production. Filter RS 305 is a compact, precise and reliable machine. It features the well-proven characteristics of Risco servo-driven fillers, namely durability and reliability. This model is equipped with a new multi-function HMI. HMI enables direct and efficient monitoring of the entire machine in order to speed up and optimize daily food production. Furthermore, the operator can easily recall all production programs and immediately switch to other products. In addition, the filler RS 305 is extremely versatile and suitable for any food processing. The optimized feeding system enables perfect filling of the Risco LongLife pump. Thus, you can achieve gentle and precise filling of any type of sausage or food. Furthermore, you can connect the RS 305 filler to all Risco accessories from the advanced range. In this way, you can get an optimal and wide production system.

Total vacuum filler for molded ham and small pieces of meat

The RS 615 from the Risco top series of machines is the ideal filler for the production of molded ham from small pieces of pork, beef or poultry with a weight of individual pieces up to 500 g. This ensures a denser, better quality product, with an improved and tastier appearance when cut. Thanks to extremely precise portioning and a continuous, automatic and precise filling process, this model perfectly meets the strict requirements of large industry. The RS 615 can be connected to any automatic shearing machine of the latest generation or to a single-head (RS 117) or double-head (RS 117.2) dosing system for portioning directly into molds or thermoforming machines.

Injector – RPI 46 – RPI 66/123

Robust construction and compact design Wing locks and adjustable feet in a hygienic design Direct mechanical drive for the needle head and belt above the drying chamber Precise needle heads with quick-change needle bridge system Mechanical or pneumatic suspension of each individual needle for products with bones Complete separation of the entire pump circuit from all electromechanical components Centrifugal pump made of stainless steel Triple filter system (mechanical or automatic) Easy to clean, hygienic industrial design Different tape strokes for flexible stitch patterns High-quality graphic panel with integrated PLC function